|

|

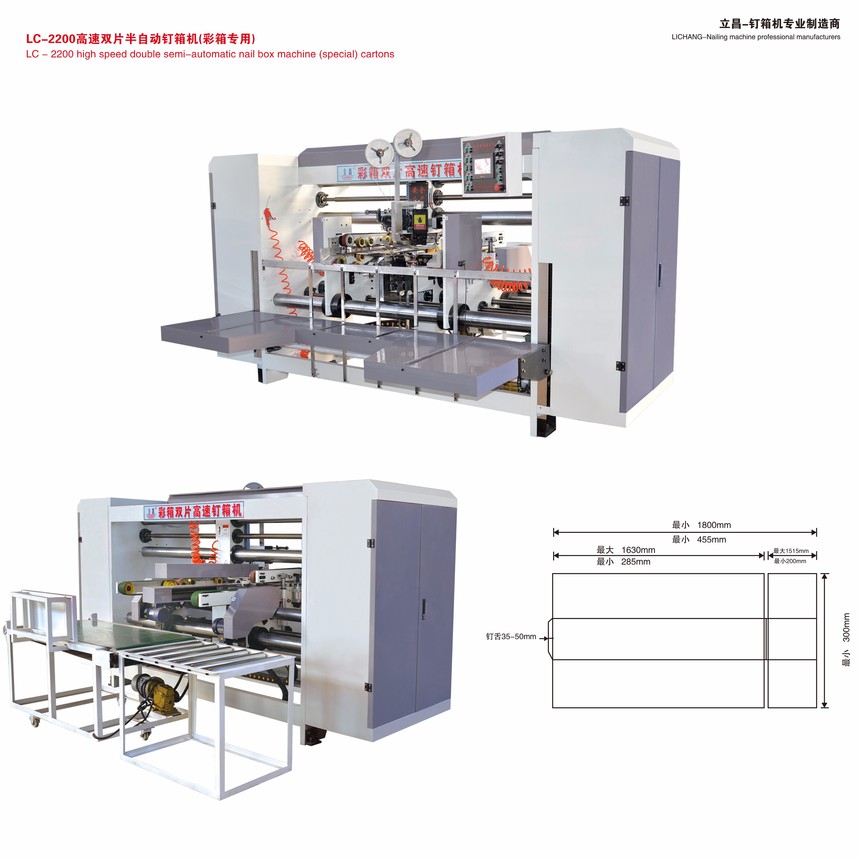

商品说明

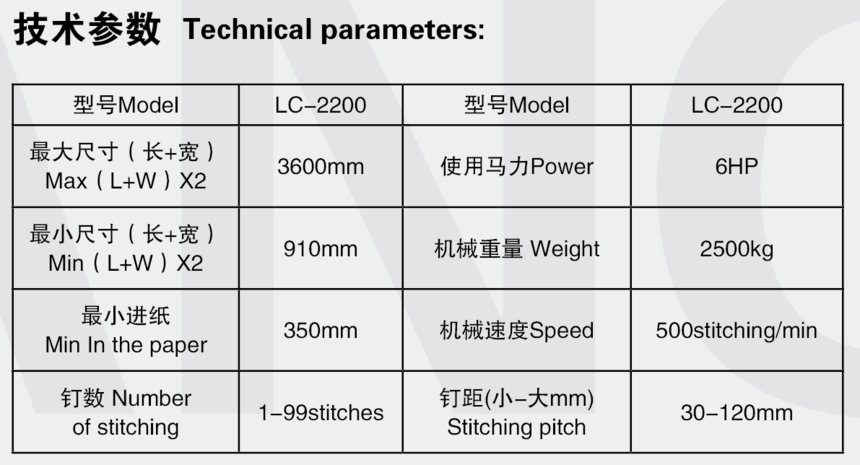

功能与特点: ◆ 机器两侧铸铁墙板增加机器整体平稳性,机械速度500钉/分钟。 ◆ 触摸屏人机界面显示,PLC控制系统 ◆ 伺服马达直接驱动钉机头,电动调整后档板确定第一钉位置。 ◆ 钉机头,左右两侧挡板可电动横移,可装钉不规则纸箱。 ◆ 左右两侧挡板同步齿形带压送纸板进入,降低了纸箱剪刀口的出现,使纸箱工整、美观。 ◆ 装钉方式有单钉、双钉一次完成。 ◆ 电脑设定自动调整钉距,使钉距均匀、美观。 ◆ 接纸部自动计数,成束送出捆绑。 ◆ 进纸料台、光电控制、自动上升。 ◆ 适用三、五层纸板,有底无盖可以钉(七层纸板需提前说明)扁丝型号:17#(2.0×0.75) 本机可选装大盘自动送丝机构。 Functions and features: ◆ Machines on both sides of the cast-iron wallboard increase overall stationarity, binding speed 500 / min. ◆ In pieces touch screen man-machine interface display, PLC control system. ◆Servo motor direct drive screw head, electric adjustment, after the first nail file cardboard to determine position. ◆ Nail head, left and right sides of the cardboard can be transverse electric moving, can bind the irregular cartons. ◆ Pieces left and right side boards synchronous cog belt press send board to enter, to reduce the appearance of the carton scissors mouth make carton neat, beautiful. ◆ Mixer is installed has single, double screw nail way . ◆ Mixer set computer automatically adjust screw pitch, nail spacing uniform and beautiful. ◆ Pieces to send paper, automatic counting, bundle or not sent. ◆ Pieces into the paper machine, photoelectric control, automatic rise. ◆ For three, five layers of cardboard, without cover and bottoms can nail (need) instructions in advance seven layers cardboard flat wire type: # 17 (2.0 x 0.75) The machine options market automatic wire feeding mechanism.

商品参数

所有评价(0)

|